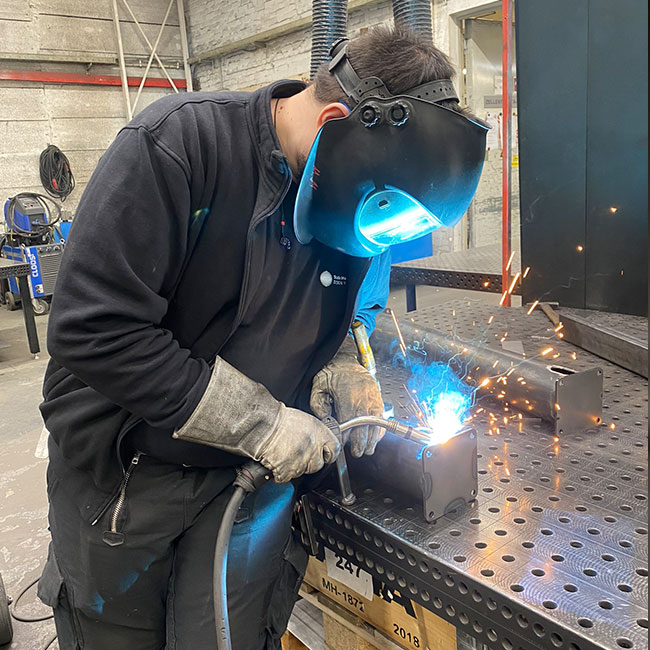

- 11 qualified metalworkers, specializing in construction

- DIN EN 1090 part 2 steel and part 3 Aluminium certified specialist welders

- Approximately 700m² of production area

- CNC – water jet cutting system, working surface 3000 x 2000mm and thickness up to 40mm depending on material

- CNC – Profile bending machine

- CNC – milling equipment

- CNC – controlled folding bench, machining length up to 3000mm and material thickness up to 5mm

- CNC – thorn bending machine (up to 48 mm round tube thickness)

- Sheet metal cutter up to 3000 x 5mm

- Kaltenbach circular saw with cutting adjustment up to 180°

- Band saw and circular Aluminium saw

- Modern welding stations with jig for dimensions up to 7000mm long and 3000mm wide

- Modern MAG welding equipment for steel work an MIG pulse systems for Aluminium work

- Plasma cutter

- Stud welding unit

- Hole punch (up to 15 mm deep by a 20mm hole diameter)

In the TV Studio

- Support construction for decorative elements

- Podium and furniture construction

- Support structures for hanging frames

- Monitor and screen mounts

- Stands and manufacture of self-propelled structures

- Profile milling for circle, ellipses etc.

In Theatre

- Manufacture of portal frames

- Platform and floor construction

- Stairs and railings

- Hanging fixtures

- Framing

- Pneumatics

- Bespoke steel and Aluminium constructions

- Profile milling of circle, ellipses etc.

Contact:

Alena Hintz

Telephone: +49 (0)40 6688-3372

E-Mail: a.hintz@studio-hamburg.de